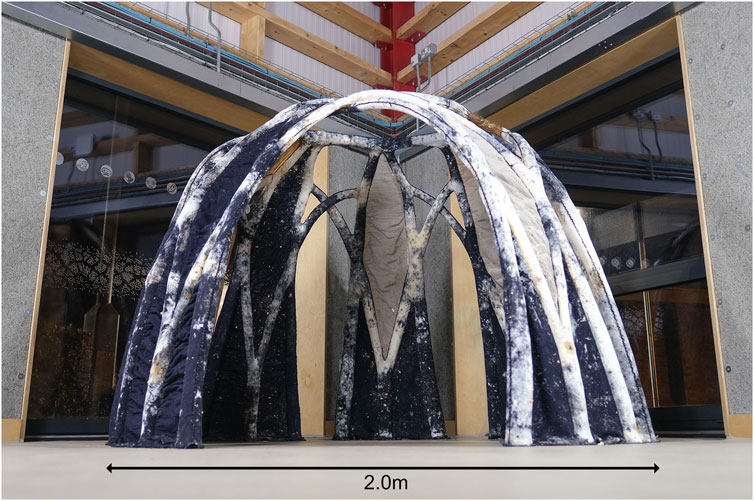

For The Newcastle Late Shows 2025, the historic Coach House in Charlotte Square hosted a living bio sculpture named Pupa. This mycelium-based installation, developed by the BioKnit team, explored how textiles, biotechnology, and architecture can come together. The BioKnit Pupa installation transformed The Coach House into a living laboratory, where fungal mycelium grows and weaves through 3D knitted fabric to form a series of organic arches and canopies.

This installation, using wool sleeves filled with waste paper and other waste products as a substrate, demonstrates possible uses for mycelium in construction. BioKnit’s approach introduces significant advancements in how mycelium structures are made. They uniquely combine permanent knitted fabric with a new, thick mycelium mixture called mycocrete. This method notably improves the material’s strength and overall performance, making it suitable for larger building components. The development of mycocrete is particularly important, as its precise formulation allows for injection into slender fabric tubes, ensuring an even fill and consistent growth—a major advancement over traditional hand-packing methods that often led to uneven growth and weaker structures.

Improved Performance and Safety

Furthermore, BioKnit has achieved dramatic improvements in the mechanical performance of these materials. Research indicates that their composites are remarkably stiff when bent, showing a 16-fold increase in flexural modulus (meaning they are 16 times stiffer against bending) and a 4-fold increase in flexural strength (meaning they are 4 times stronger against bending until failure) compared to conventional mycelium composites. They also demonstrate enhanced compressive strength and stiffness. This significant leap in performance is critical for transitioning mycelium from small-scale applications, such as packaging or insulation panels, to self-supporting architectural structures. The knitted fabric formwork acts as a vital reinforcement, preventing sudden, brittle failure and allowing the material to continue bearing some load even after initial damage. This provides a crucial safety mechanism, similar to the behavior of ductile structural steel in construction.

Towards a Regenerative Future

BioKnit’s vision is “one where Built environments are life-sustaining and sustained by life.” Their mission is “to develop biotechnologies to create a new generation of Living Buildings which are responsible and responsive to their natural environment; grown using living engineered materials to reduce inefficient industrial construction processes; metabolise their own waste, reducing pollution, generating energy and high-value products; and modulate their microbiome to benefit human and ecological health and wellbeing.”

This aligns with the work of Ben Bridgens, Professor of Regenerative Architecture at Newcastle University and a founding member of the Hub for Biotechnology in the Built Environment (HBBE, www.bbe.ac.uk). Professor Bridgens’ work is driven by the question: “Can we move beyond ‘sustainability’ and create a built environment which has positive impacts: that is beneficial and enriching to the natural environment, that does not degrade but performs better as it ages, that is a pleasure to construct, and is delightful to inhabit?”.

He works at the interface of engineering, architecture, and design, critically examining ‘sustainable’ technologies and exploring the potential for combining traditional construction practices with biotechnology and natural systems to go beyond sustainability and create a regenerative built environment. BioKnit’s low-energy and carbon-neutral manufacturing process, utilizing agricultural by-products, directly supports the urgent need to reduce the construction industry’s climate impact. The successful creation of prototypes, such as the 1.8-meter high freestanding arched dome, further demonstrates the potential for lightweight construction and complex forms.

This pushes beyond the limitations of traditional mycelium bricks and paves the way for a new class of textile biohybrid composite materials that are both structurally sound and environmentally beneficial. Just as Gaudí used polyfunicular models (complex hanging models made of multiple chains and weights to find ideal shapes) to achieve complex, interconnected catenary forms (the natural curve a hanging chain makes), BioKnit’s approach supports intricate, efficient designs.

Source Material for this Content

The information presented in this essay is drawn primarily from the scientific article “BioKnit: development of mycelium paste for use with permanent textile formwork,” published in Front. Bioeng. Biotechnol. on 14 July 2023 (https://doi.org/10.3389/fbioe.2023.1229693). Additional insights into the vision and mission of BioKnit and the broader context of regenerative architecture are sourced from public information related to Ben Bridgens, Professor of Regenerative Architecture at Newcastle University and a founding member of the Hub for Biotechnology in the Built Environment (HBBE, www.bbe.ac.uk).

Where next? Use the links below:

Snippets: Curated collection of short, impactful articles and inspiring ideas.

Forward Futures: Actionable essays delving into contemporary issues.

Grasp the Nettle. Table of Contents: A book in progress charting paths toward a more empowering future, for a global audience.

About: Our mission – From Awareness to Action.